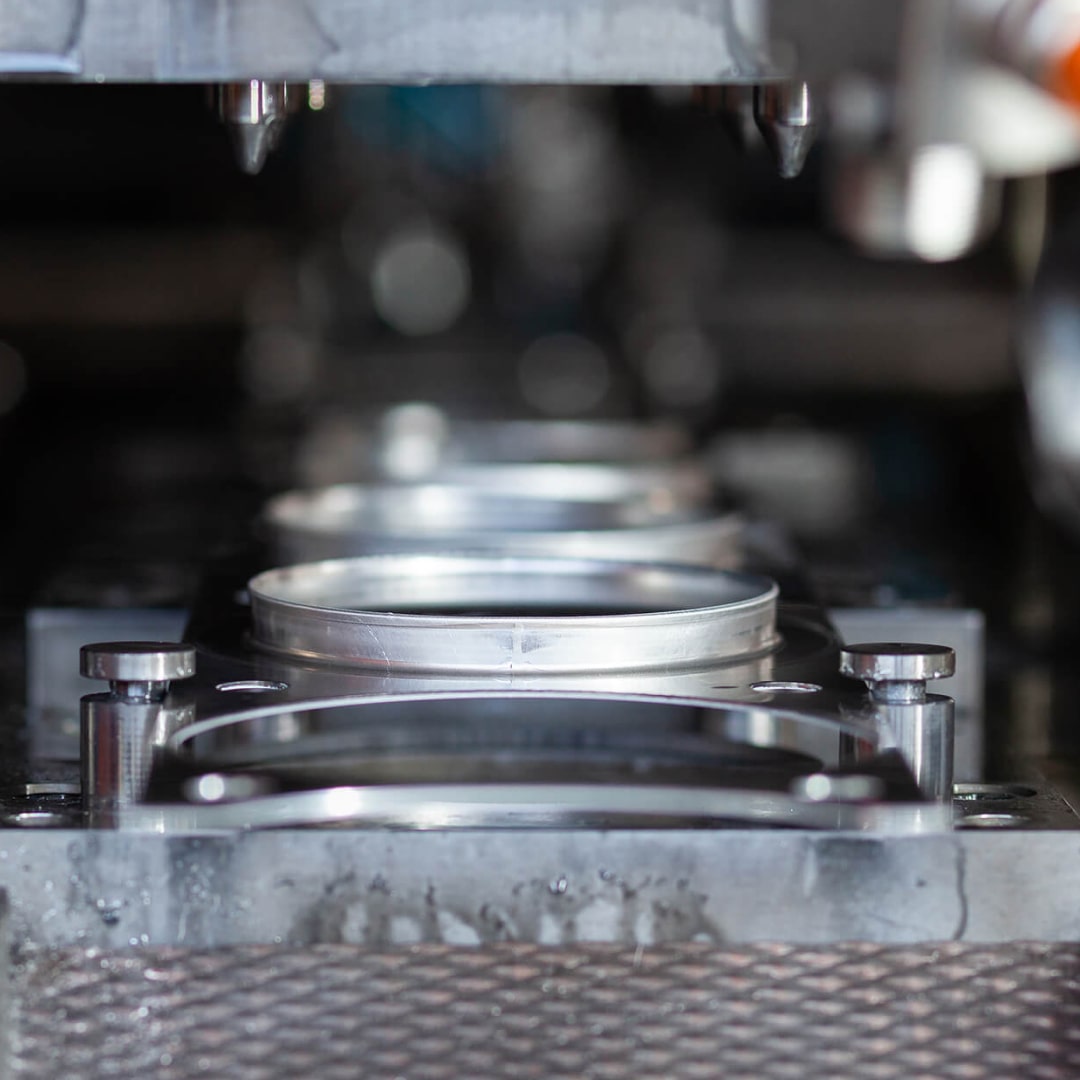

The company REL srl, located in the town of Lecco, was founded in 1985 by the present owner and managing director, Mr. Lorenzo Gianola, and since then it has always been specialized in plate pressing.

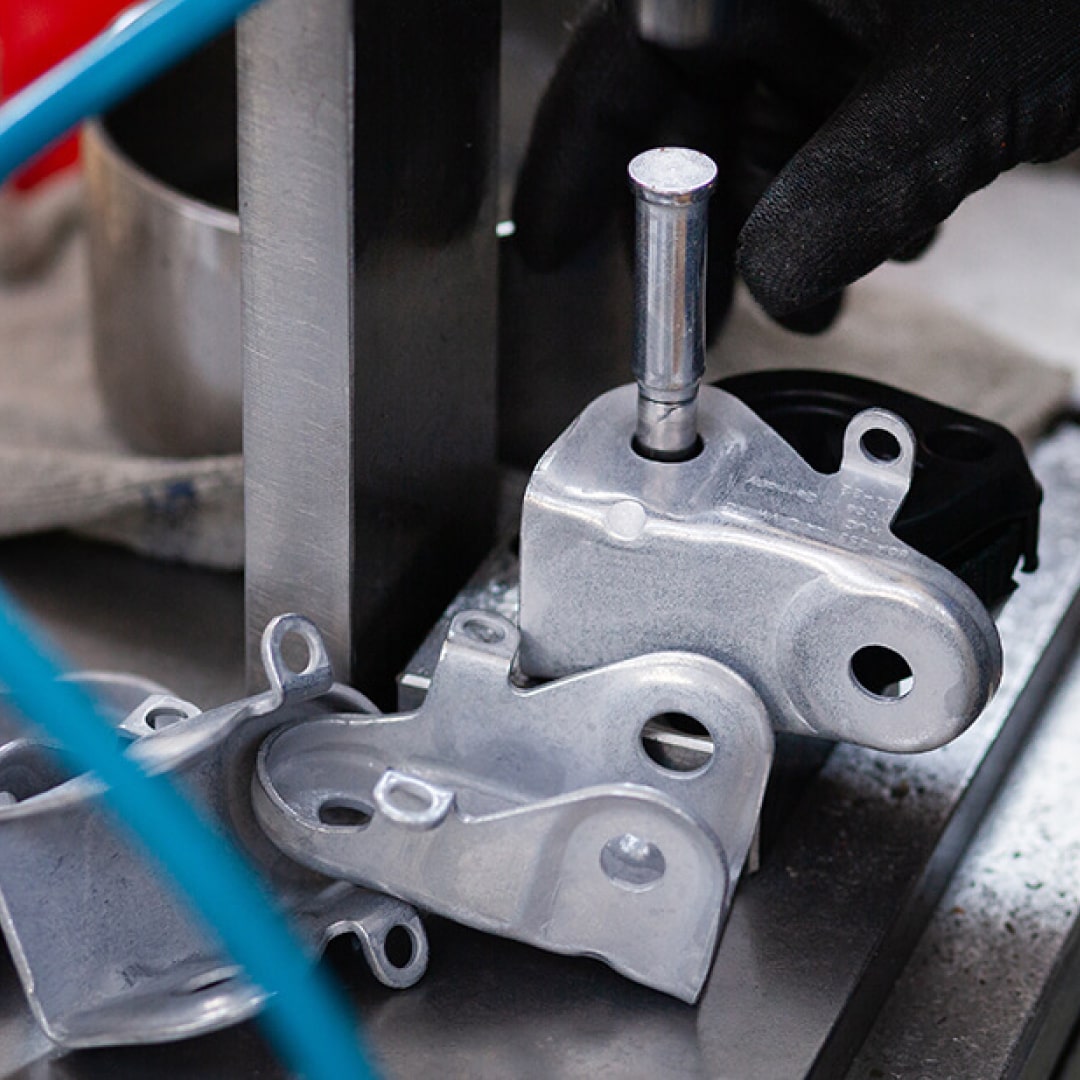

The factory includes departments for complementary machining, for the eventually required finishing of the pressed workpieces, such as MIG welding, resistance welding, spot welding, drilling and tapping operations, manual and automatic assembly of components. Moreover, the company offers to its customers also the service of industrial cleaning for the finished or semi-finished workpieces.

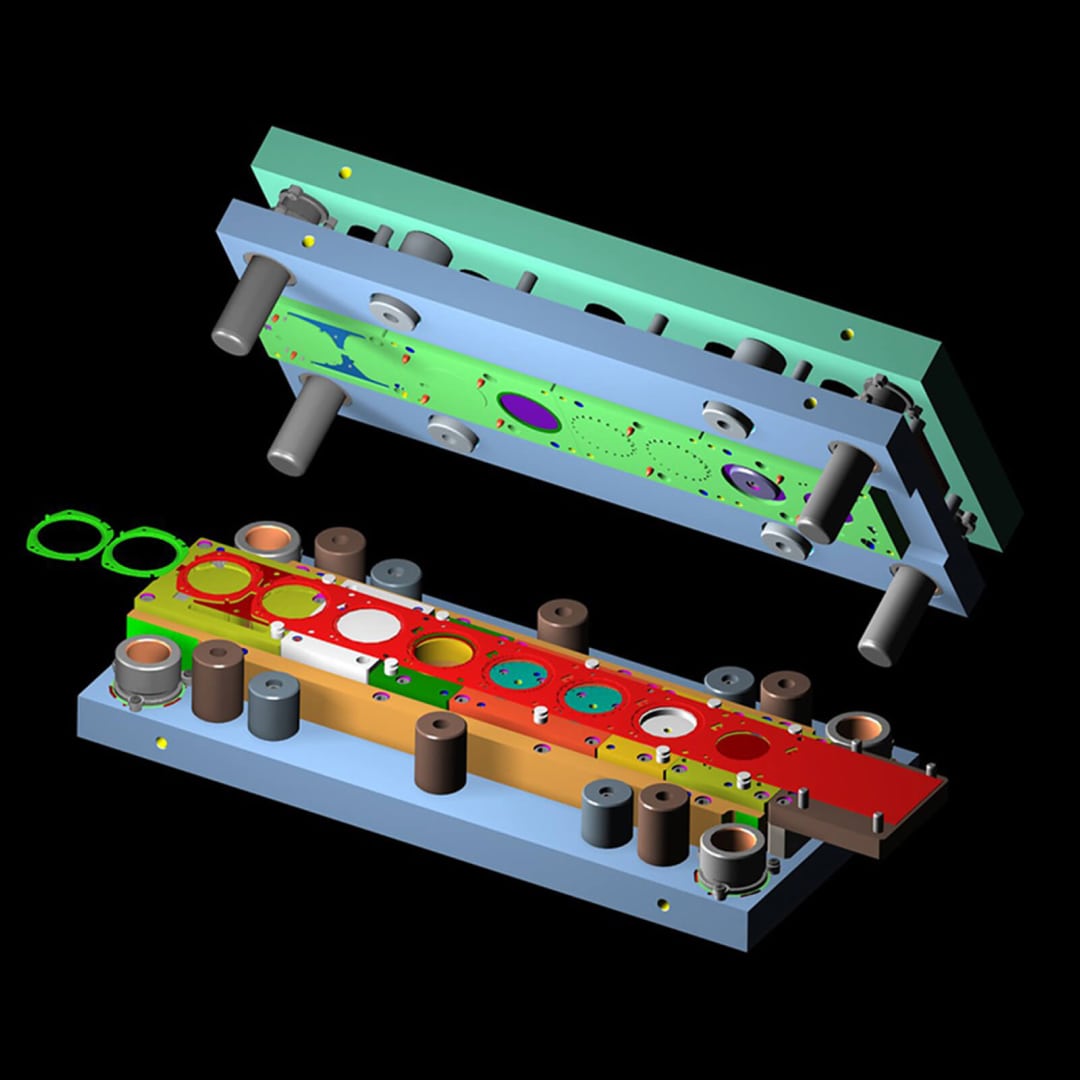

For the workpieces manufacturing, the Company REL srl has decided to invest in its technical office, for the industrialization of the products in co-design with the customer, for the design and the manufacture of the dies necessary for the production of large batches ; this can be done also taking advantage of an advanced and well equipped tooling department.

124,50 MWh

Total energy produced

1'500,00

Equivalent trees planted

49'000,00 Kg

CO2 emissions avoided

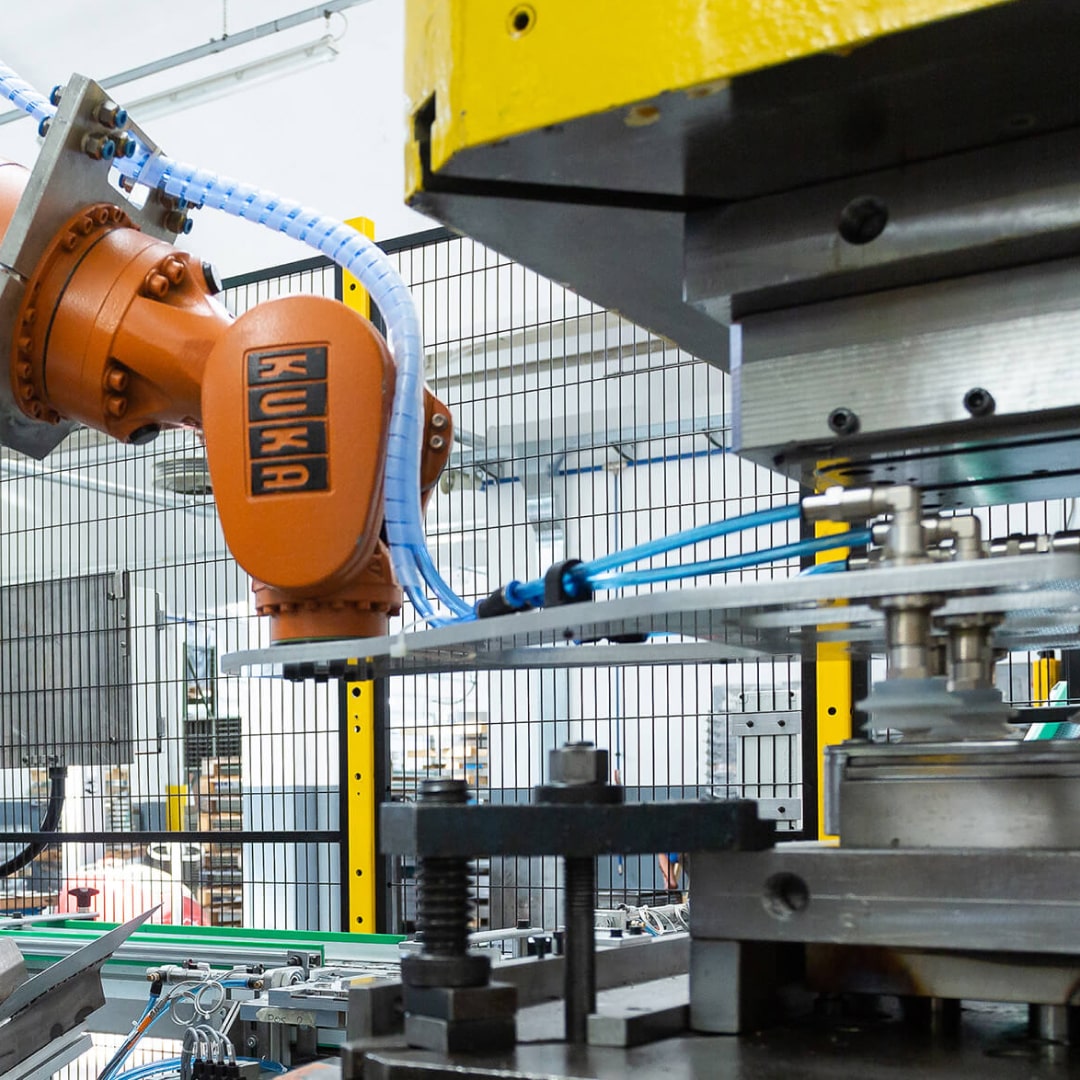

RESEARCH AND DEVELOMENT

The constant investments in the “research and development” department and in the workshop equipments, as well as the careful control of the production process, allow to the company REL srl to reduce the production cost, always ensuring the best quality. This is why the customers give in charge their production in outsourcing to REL srl. Our customers know that they can rely on a long experience, on the most advanced machine tools, on specialized staff and on optimal costs control.

Moreover, REL srl always tries to optimize all steps of the factory working process, always taking into consideration the new technologies offered by the market.

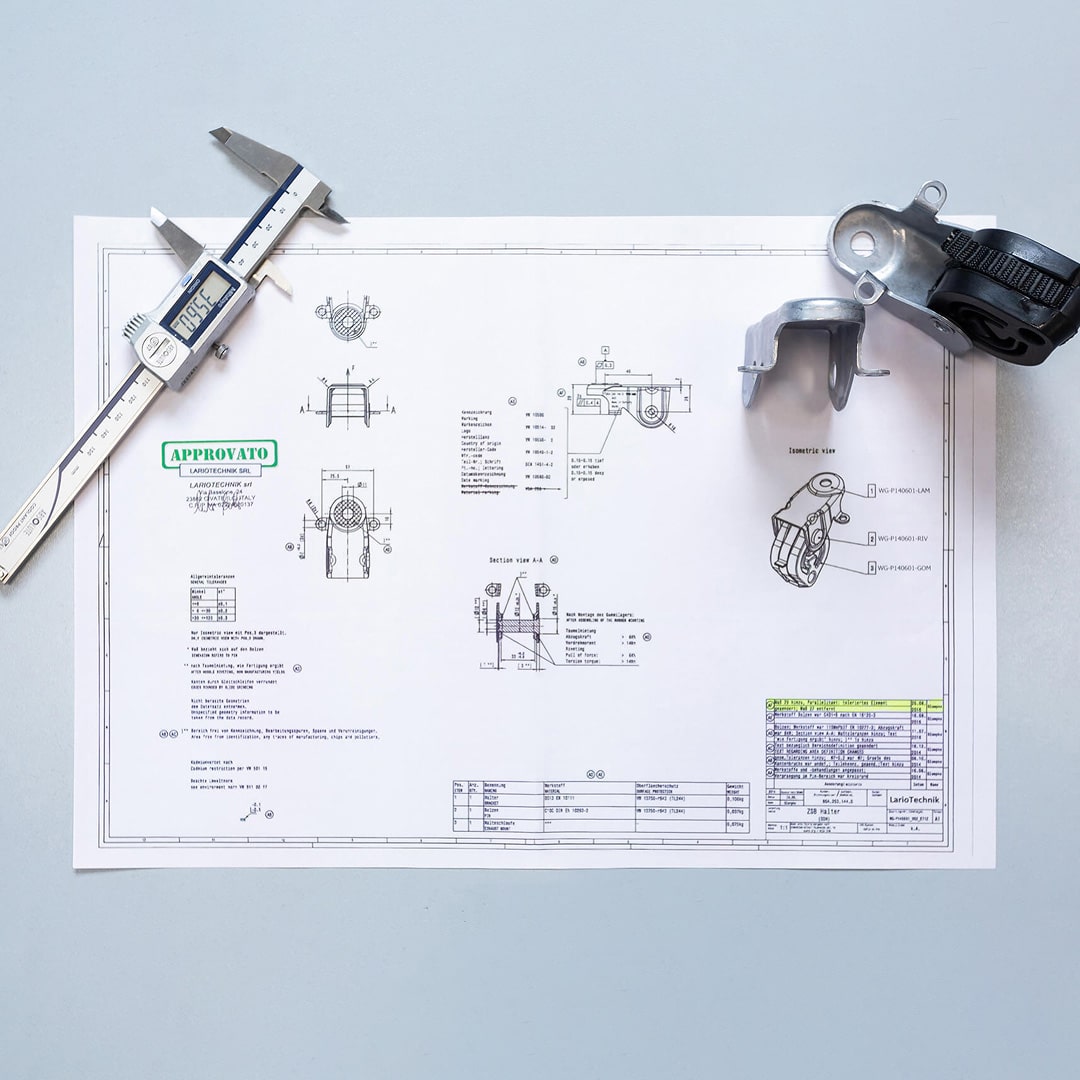

TRACEABILITY

REL srl assures the customers a complete traceability of the product and of all factory processes, such as the design, the tooling manufacture and the batch production; the whole process is carried out and monitored according to UNI EN ISO 9001 : 2015 directions.

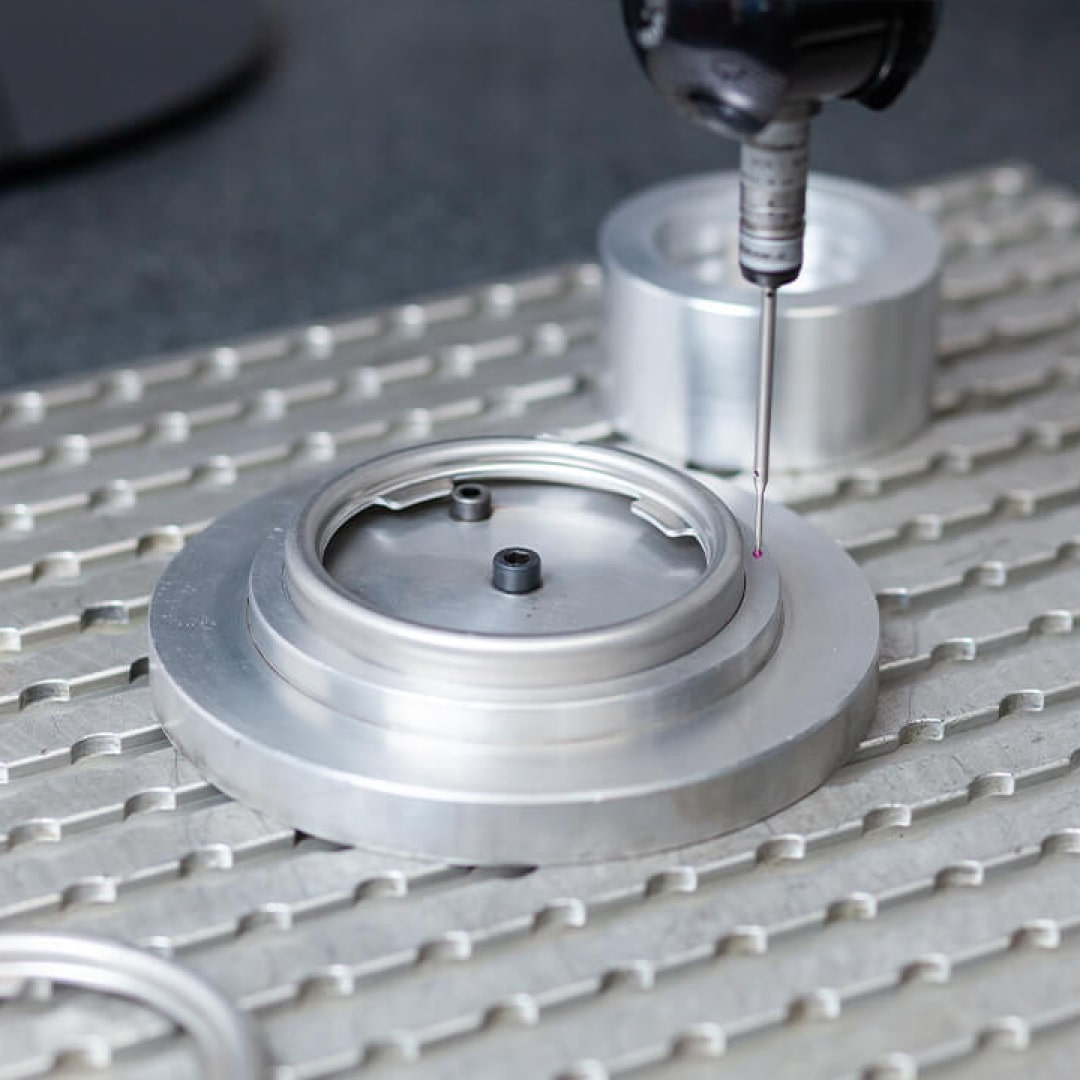

QUALITY CONTROL

REL srl has always cared to assure very high quality standards, making use of the best equipments according to the product type, such as the tridimensional measuring machine, the digital optical microscope, calipers and inspection fixtures, customized according to needs.

Thanks to all these equipments, the company is sure to deliver a finished product at the state of the art.