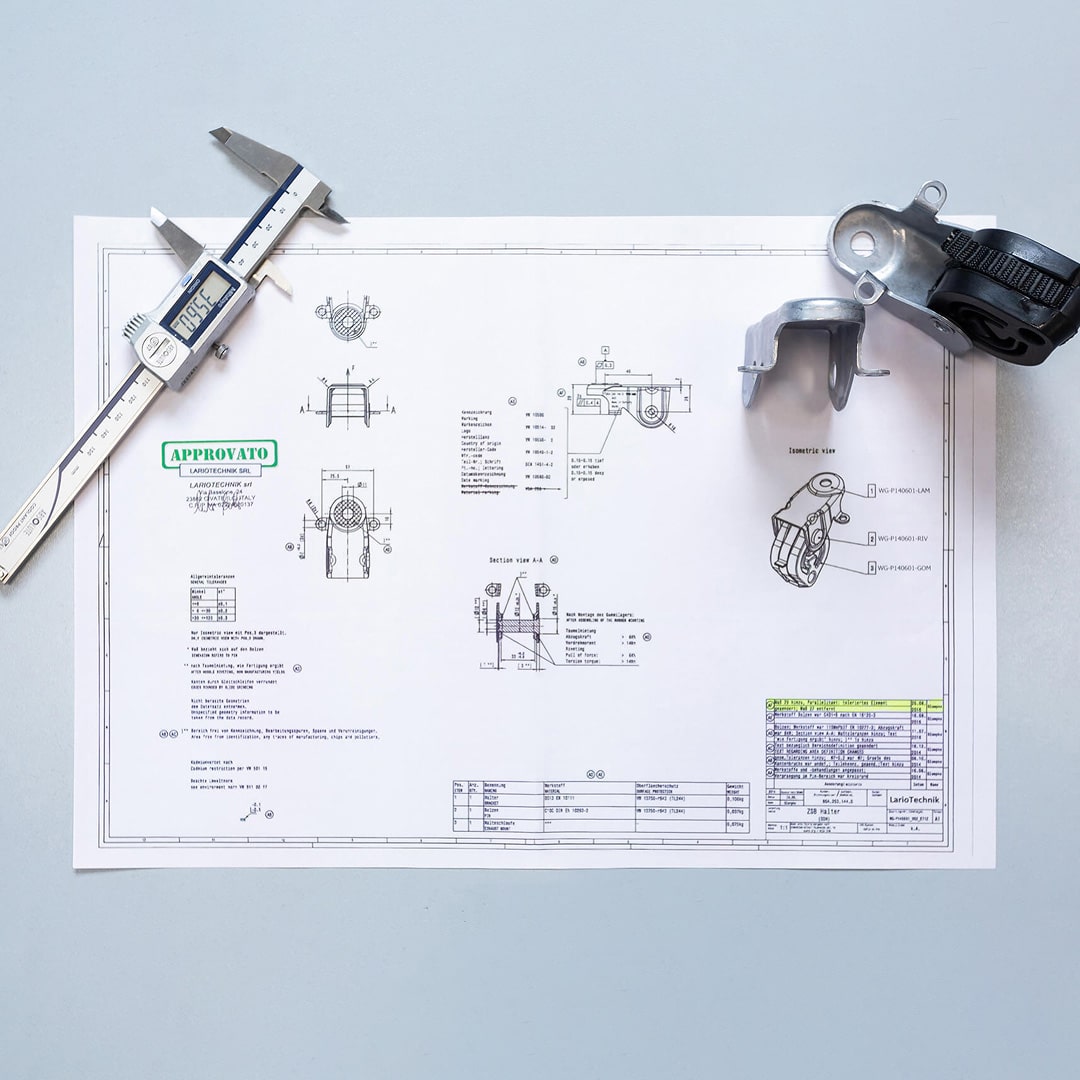

REL srl offers the manufacture of pressed workpieces, according to customer’s specific drawing, or also studied in co-design with the customer himself. The technical department of Rel srl designs and manufactures the dies in-house, to carry out the subsequent production. Always in-house, the technical department is able to realize tooling and automatic plants for the products assembly.

A peculiar quality of REL srl, greatly appreciated by main customers, is the capability to design and manufacture pilot-dies in a very short time, for the realization of prototypes for new products; this can also be made in cooperation with the customer, in order to develop the best technical/economic solution for the subsequent batch production.

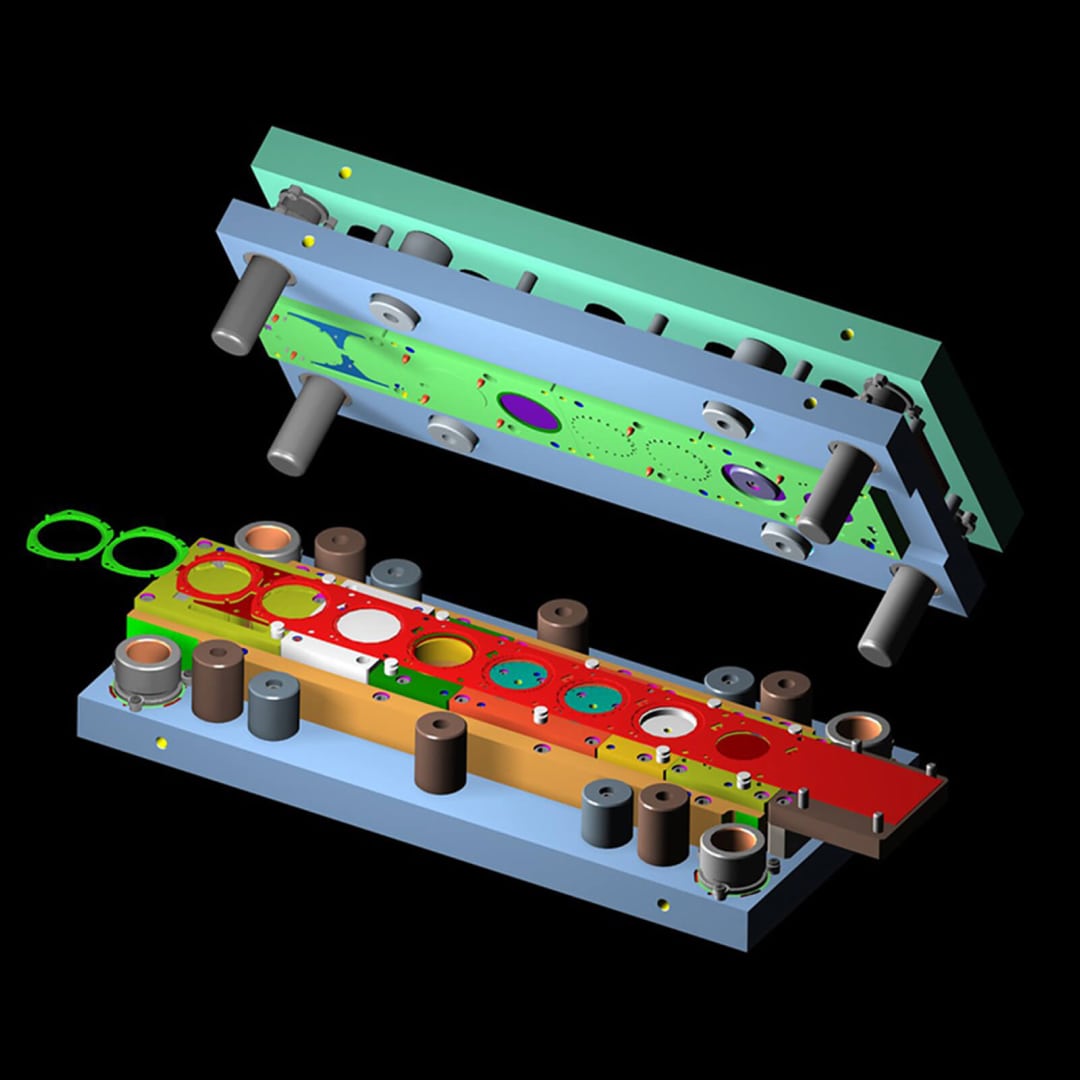

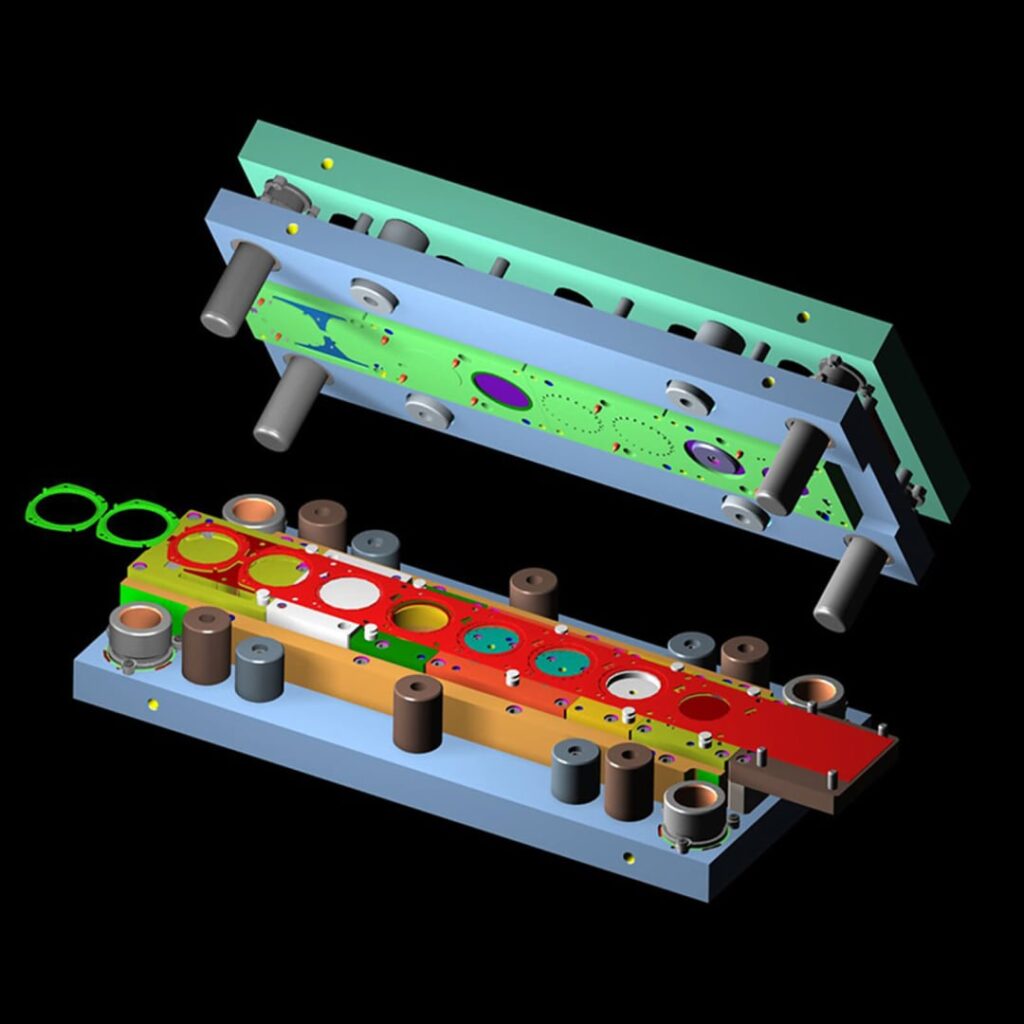

Design

Our in-house department transforms ideas into finished products through research, engineering, and simulation. We also manage the design of special machines for specific tasks in-house, supporting every stage of development. This integrated process ensures tailor-made solutions and maximum efficiency.

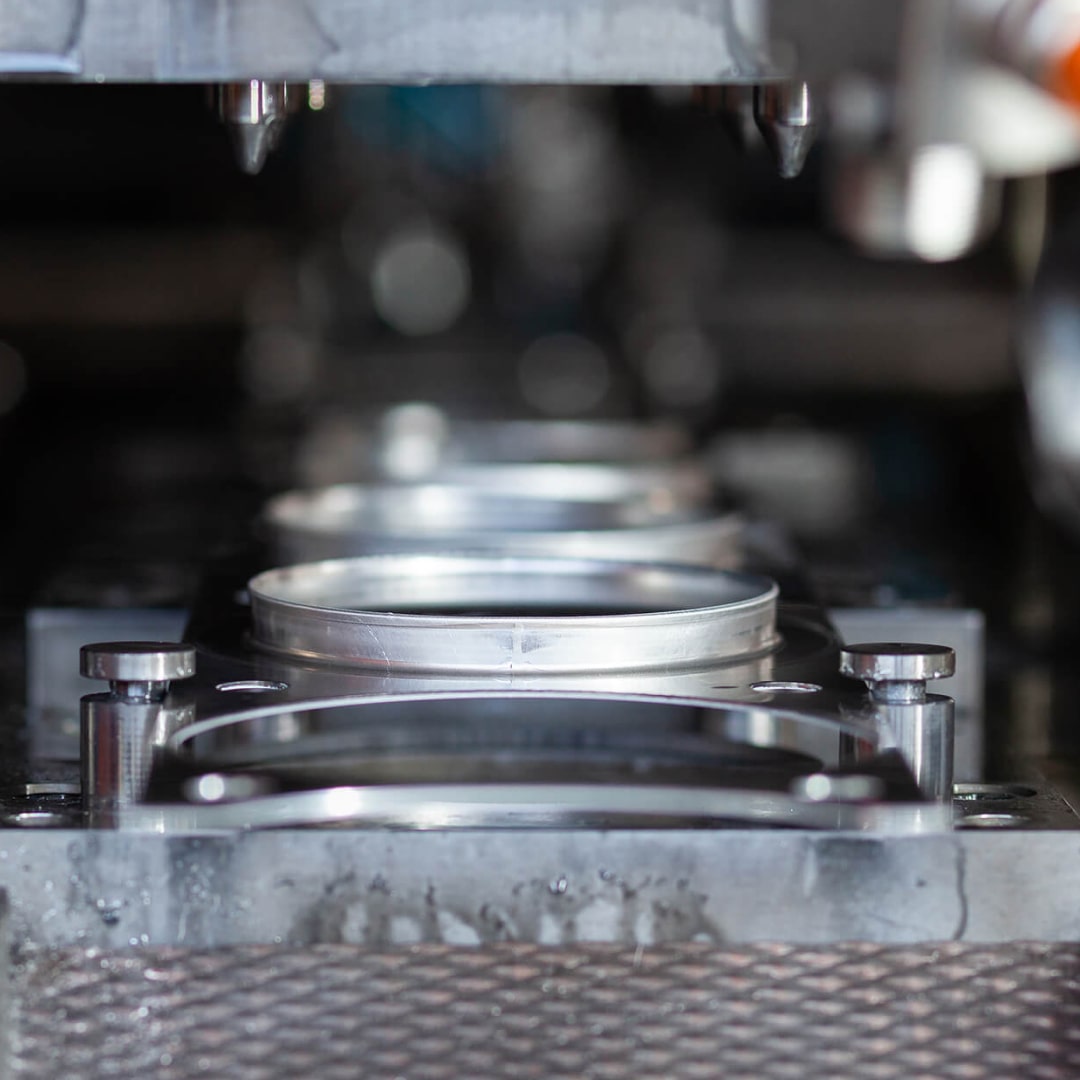

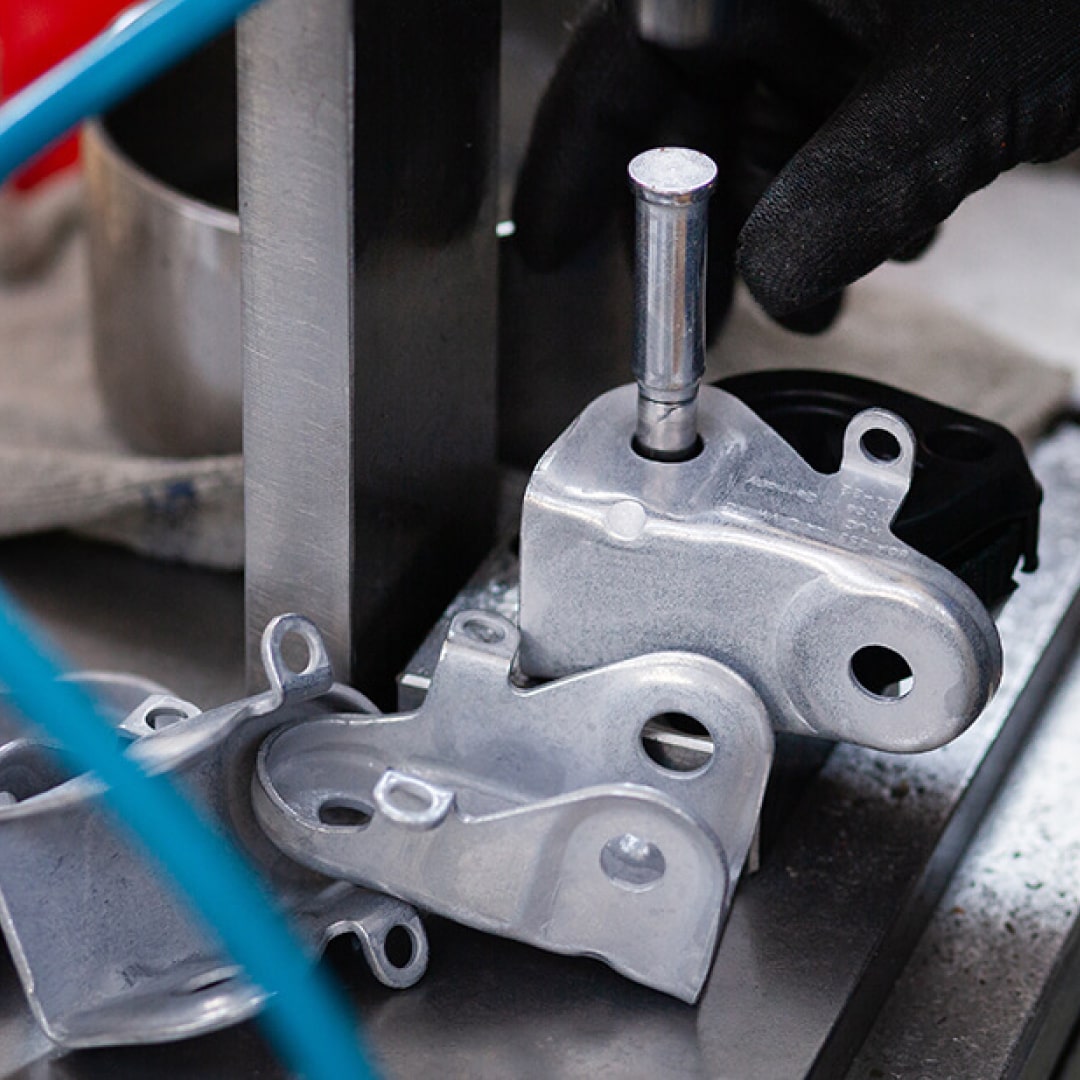

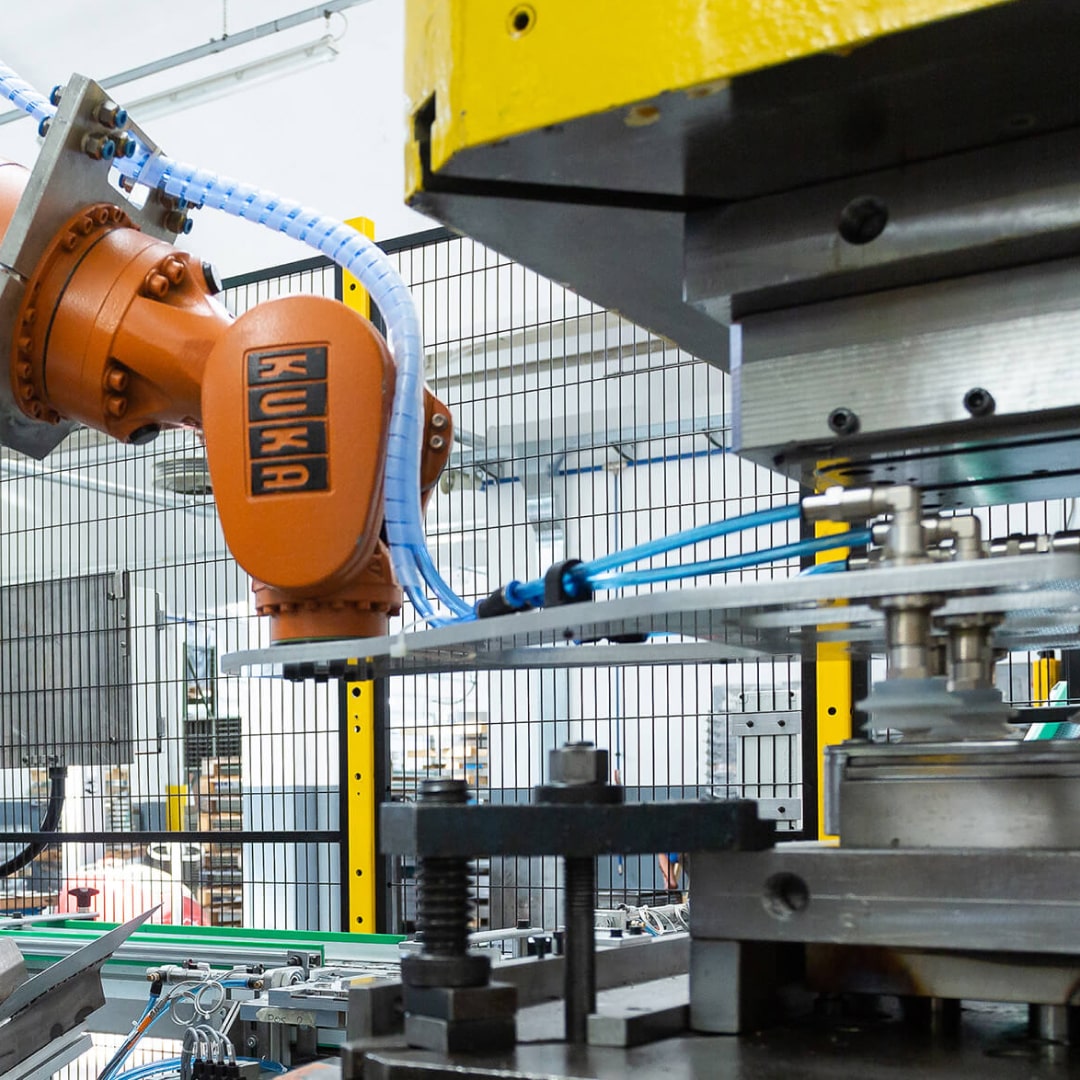

Manufacture

With CNC centers, grinding machines, EDM machines, and lathes, we build block, pilot, and progressive dies, as well as special machines for internal use. The high technology of the machinery and the expertise of our staff guarantee excellent quality standards, responding precisely to customer requests.

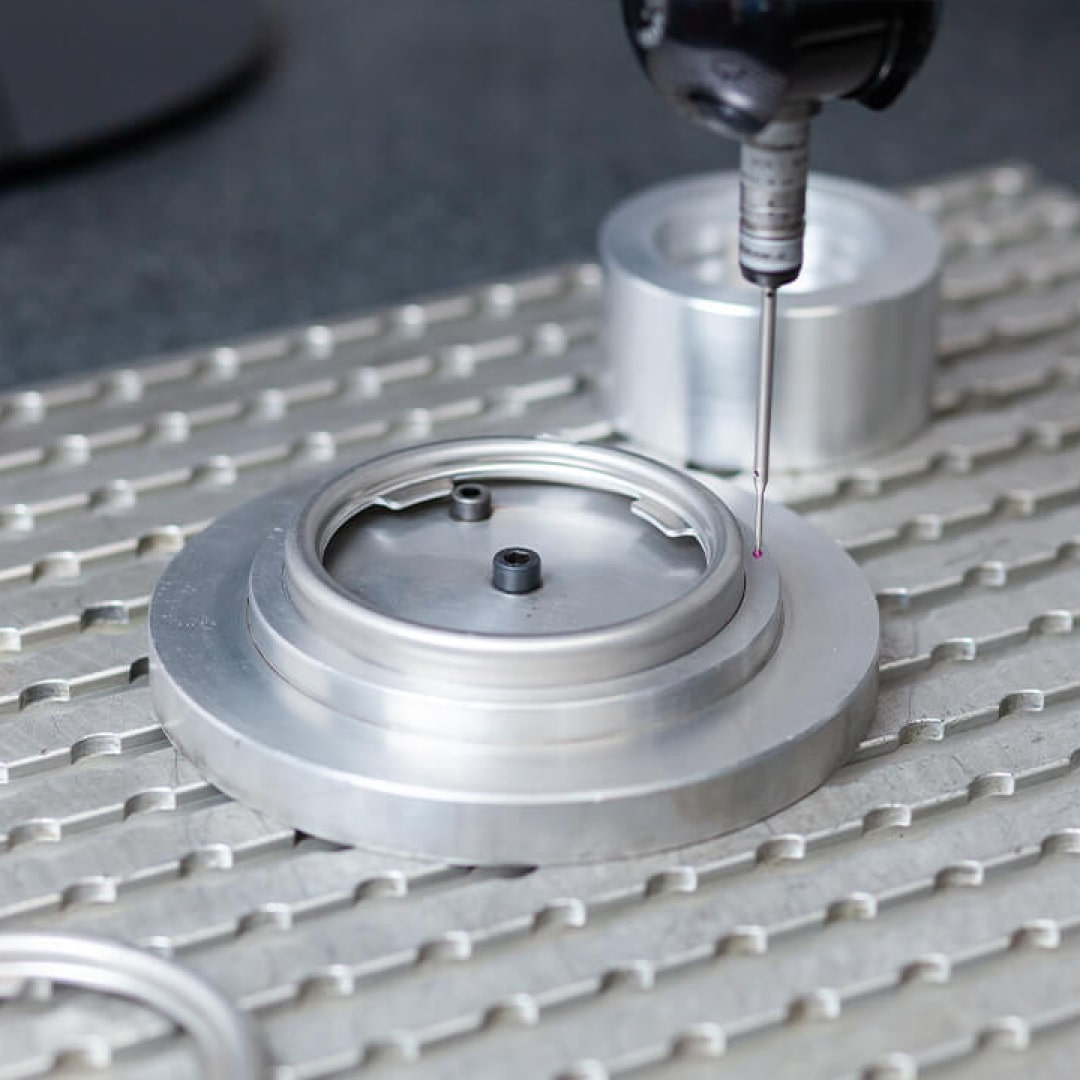

Samples and prototypes

We carry out deep drawing simulations, prototypes, and pilot dies to test products before final industrialization. This activity by our technical staff is crucial for validating the design, optimizing production costs, and ensuring the success of the final component on a large scale.

Specialized TIG Welding for the Repair of Dies and Punches

The TIG welding department specializes in the restoration of dies and punches. We intervene on worn edges, cracks, or machining errors to reduce maintenance costs. The service guarantees precision and reliability in the recovery of equipment, extending its productive life.